I keep seeing gravel bikes getting a bad rap, with countless videos and articles on the internet questioning the need for gravel bikes – especially from UK journalists. They’ve been called a marketing gimmick to help the cycling industry sell more bikes, and a fad. I don’t agree. I believe the motivation for gravel bikes is either misunderstood, or factors that make them relevant in the USA don’t exist in the UK.

What is meant by a gravel bike?

A gravel bike is a type of bicycle intended for cycling on unpaved roads – generically referred to as ‘gravel’ roads. While bicycles have been ridden on gravel roads since bicycles were invented, gravel bikes evolved as a category of bikes adopting features and technologies from road, cyclocross and mountain bikes to hone their performance on gravel roads.

Common features of gravel bikes include:

- 700c or 650b wheels – the same as road or cyclocross bikes.

- Clearance for tires 40 mm or wider. Road bikes are typically limited to 30 mm, cyclocross bikes are designed around the UCI maximum tire width limit of 33 mm, mountain bikes typically run 2.3 – 2.5″ (58 – 63 mm).

- Drop handlebars like a road or cyclocross bike to put the rider into a more aerodynamic riding position.

- Frame geometry is optimized to provide comfort on long rides with stability at speed. Cyclocross bikes are optimized to provide agility on tight courses for a race lasting less than an hour.

- Gravel bikes typically have no suspension (like road or cyclocross bikes).

- Gearing is higher than a mountain bike for higher speeds on flat roads, but lower than a road bike to help with steeper, looser climbs. Gravel bikes either have a single chainring like a mountain bike with around 40 or 42 teeth compared to a mountain bike that may have a single 30 or 32 tooth chainring, or double chainrings with 46/30 or 48/31 compared to a road bike with 50/34, 52/36 or 53/39.

- Typically have mounting points for more than two water bottles and possibly mounting points for racks, packs and bags to support long rides, or multi day rides. Traditionally, cyclocross bikes typically didn’t have mounts for water bottle cages as cyclocross racers didn’t need to carry water for an hour long race.

- All gravel bikes have disc brakes as rim brakes can’t be used with the wide tires used on gravel bikes.

The first gravel bike was the Warbird introduced by Salsa Cycles in 2008. It’s no coincidence that Salsa is based in Bloomington, Minnesota which is in the heart of the midwest. The Warbird was introduced to address some of the deficiencies of cyclocross bikes that were used for gravel racing at the time.

Below is a map of the south of the lower peninsula of Michigan from gravelmap.com which is a route planning website for gravel cyclists. The US is a vast country with areas that are sparsely populated. The total area of the state of Michigan is around 100,000 square miles with a population of 10 million people, giving an average population density of 100 people per square mile. By comparison, the UK has an average population density of 671 people per square mile.

As most of the population is focused around cities, the population density in the large rural areas is vey low.

Many roads in the the sparsely populated rural areas are unpaved and consist of hard-packed dirt and gravel. I though this bizarre when I moved from the UK to the US. I can’t think of any public roads for vehicular transport in the UK that are unpaved – and this is an important difference where gravel bikes are concerned. As a result, in the US there’s a network of thousands of miles of gravel roads. The cyan and green roads shown on the map above are gravel roads.

I can leave home on my gravel bike, the nearest gravel road is 3 miles away, and from there I can put together a ride of 20, 30, 50, 100 or more miles, mainly on gravel roads with only short sections on the busier paved roads.

The roads are generally smooth to ride on, like riding on a paved road but without the cars. There are no roots, rocks or technical challenges, it’s essentially like riding a road bike, but on a road made up of dirt and gravel. It’s peaceful, out in the country side – away from it all.

The dirt roads are regularly graded to remove potholes, ruts and washboard that develop over time due to weather and traffic, and to maintain a crown on the road.

While it might be possible to get away with a road bike and 30 mm tires on some sections of dirt road, having wider tires helps where there are sections of larger loose gravel or sand. Larger tires also provide some relief on rough sections of road with potholes and washboarding.

There have been plenty of times where I’ve unexpectedly hit washboard, potholes, or sections with chunks of large loose gravel at speed, and been glad to have been on a gravel bike with 40 mm gravel tires rather than a road bike with narrow tires.

Suspension may be useful in these instances, but typically these are only short sections of bad road. I’d rather not carry the extra weight of suspension just for that. I also like to be able to get out of the saddle without putting pedaling effort into suspension. If a section of road is bad, then it’s normally posted on one of the Facebook gravel groups I follow so I know to take a different route to avoid it.

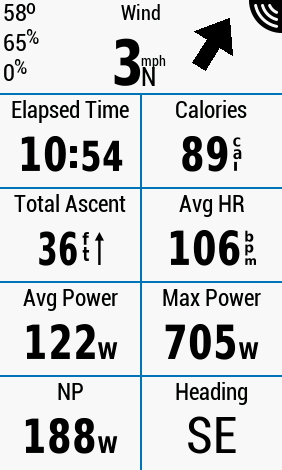

I have friends who ride mountain bikes on gravel rides. Apart from having suspension that helps deal with bad road conditions, they always seem to be at a disadvantage and are having to work much harder. When we’re riding at 17+ mph, their cadence is very high due to their much lower gearing. Their rolling resistance is much higher due to their wider knobbly tires and as they ride in a much more upright position, they’re less aerodynamic.

A typical gravel ride for me is 30-35 miles either riding on my own, with a couple of friends, or with one of the gravel groups I ride with. Depending on the group, I’d typically average something above 17 mph, but on a fast ride we could average 20 mph or higher.

One of the reasons for the popularity of gravel riding, is that it’s a safer alternative to road riding. On paved roads – based on data from my Garmin Varia – I’ll typically be passed by 5 vehicles every mile, even on the quieter roads I chose to ride on. On dirt roads, I may be passed by 1 vehicle every mile. Drivers also drive slower and are more attentive on dirt roads.

Many of the people I ride gravel with come from a mountain bike background, don’t own a road bike and aren’t interested in road riding because of the dangers. We hear of too many cases of road cyclists being killed by reckless or careless drivers, especially due to distracted driving and smart phones. I know of several dedicated and passionate roadies who now refuse to ride on the road after friends have been killed or seriously injured. Quieter gravel roads are certainly safer than riding on the road.

Gravel riding also seems more social than either mountain biking or road riding as it’s easier to hold a conversation on a gravel ride than on the road or a mountain bike trail.

Gravel racing is very popular in Michigan with a busy schedule of races across the state:

Michigan hosts the world’s largest gravel race every spring, Barry-Roubaix. There are distances of 18, 36, 62 and 100 miles and the race is always sold out with around 4,000 riders participating.

The 36 mile Barry-Roubaix was my first gravel race in 2018, which I did on a Kona SuperJake, which is a cyclocross bike. The bike was set up for gravel, meaning it had 38 mm gravel tires, it had a 2x crankset, gearing suited to the local gravel roads and it had two bottle cage mounts. Although I’d been looking for a gravel bike, this was available when I needed it, and the price was right. It was a great bike that I rode for 1,800 miles including big races such as the 210 mile Michigan Coast to Coast Gravel Race.

This was me on the front in that first race. At 20+ mph drafting is as important on a gravel bike as it is on a road bike.

Gravel races tend to include more difficult sections of road – sections that would normally be avoided. Sandy sections are popular with the organizers. The photo below was taken during the 2019 Barry-Roubaix 100 mile race. For some reason as I approached the photographer (Rob Meendering) I decided to switch from the right to the left side of the sandy double track – without realizing there was another rider, Skip, close to me. I slid out in the deep sand, went down and took Skip down in the process, right in front of the camera. A mountain bike would be great with its wider tires in sections such as this, but would be slower in the other 95% of the course. It’d be a nightmare on a road bike with skinny tires, so a gravel bike with the right 40 mm tires is ideal. You just need to exercise caution in the tricky sections!

I later replaced the Kona with a Look 765 Gravel RS gravel bike. This is a great bike, but so was the Kona. I can’t say I’ve noticed much of a difference between gravel and cyclocross geometry, either in the riding position or handling. The most noticeable difference is that the Look has mounts for two more bottle cages and for a top tube box. I have the Look set up with a Campagnolo Ekar groupset. I went for this because I like the Campagnolo groupsets I have on my road bikes. Ekar is only available as a 1x system (single front chainring). I’d normally prefer a 2x setup on a gravel bike so that I don’t have to compromise the gear range – which normally means losing high gears – but the Ekar groupset is 13 speed and I have a 9-42T cassette with a 42T front chain ring. This gives me more or less the same gearing as a 2x system. I’ve ridden the Look on fast road rides and I’ve never been short of high gears. Cyclocross bikes would normally come with a 1x groupset and 11 speed, and in that case they lose some of the higher gears.

As gravel bikes share features from mountain and road bikes, they are very versatile. Most people would agree that if you could own only one bike, then a gravel bike would be a good choice. A gravel bike can be ridden on the road in place of a road bike, or due to the wider tire clearance and more rugged construction, it can be taken off-road in place of a mountain bike. However a gravel bike won’t be as good on the road as a road bike, and it won’t be as good off-road as a mountain bike.

While the US, and especially the midwest, has the vast network of gravel roads I discussed, I feel this is unique to the US. In particular, gravel roads don’t exist in the UK like they do in the US. Sure, there are unpaved forest roads, bridleways and some private gravel roads that can be used by cyclists, but as they weren’t built for cars they’re narrower, twistier, gnarlier and not maintained in the same way US gravel roads are. These trails don’t allow the advantages a gravel bike offers over a mountain bike to be realized – gearing for higher speeds, lower rolling resistance and a more aerodynamic riding position. In the UK this then leads to the question as to their value and why they’re necessary. There’s nowhere to ride them as they were intended to be ridden, and they end up being ridden on terrain better suited to a mountain bike.

Before I moved to the USA, I lived in Hove on the south coast of England. As an avid mountain biker it was great being close to the South Downs where I rode several times a week. The South Downs is a series of hills just inland, running parallel to the coastline. The South Downs Way is a trail along the South Downs which is open to hikers, equestrians, and cyclists that runs 100 miles from Winchester to Eastborne. This is a great trail for mountain bikes, mainly made up of double track, with some steep climbs and some very fast descents, which were often rocky and a challenge to ride fast. I had my worst bike accident ever riding the South Downs when I couldn’t stop for a gate after descending Newtimber Hill at over 40 mph and face-planted into the gate post.

There are several articles and videos online showing people riding gravel bikes on the South Downs, including this video from Wahoo that shows a group riding a combination of gravel and mountain bikes on the South Downs Way.

Due to their versatility, and as the South Downs Way isn’t particularly technical, then this is totally rideable on a gravel bike. However apart from their ability to carry bags and packs for backpacking as an ‘adventure bike’ for a multi-day ride, there’s no advantage of riding a gravel bike on the South Downs Way. I think this is still a better trail for a mountain bike. There are steep climbs where lower mountain gearing would be a benefit, and sections where suspension is beneficial. Gravel bikes are being introduced with front and rear suspension and with dropper seat posts to improve their off-road capability, but I feel that if suspension and dropper posts are needed, then the trails aren’t of the type where a gravel bike would excel over a mountain bike.

The growth of gravel bikes, gravel riding and racing in the US has been phenomenal over the past five years and the growth is continuing. The Michigan Gravel Grinders Facebook group founded by my friend Jill in August 2020 now has 4,200 members. This is a very active group with several gravel group rides each week. Another group I ride with, the Monday Night Gravel Grinder can have 20-30 riders on their weekly group ride, and the Gearheads group consistently has 10-15 riders each Thursday night. The groups have riders of all abilities, some who race and use the rides for training, others who have just got into cycling, or ride on the road or mountain bike and have started gravel riding. There are many established road cycling groups and mountain bike race teams in the area, and most of these have gravel rides and participate in gravel races. The number of gravel races is continuing to increase along with the number of participants. The big races such as Barry-Roubaix sell out quickly, and due to the high demand, there’s a lottery process to enter the Unbound Gravel race.

You don’t need a gravel bike to join these rides or races. People will ride what they have. There are mountain bikes, cyclocross bikes, some even get away with riding road bikes. However due to the popularity of gravel in the US, there’s a large market for gravel bikes, and the cycling industry is responding to the demand – not than pushing an unnecessary product onto the cycling public. I don’t know that this is the same in the UK. If I was still in the UK I think it’d be unlikely I’d own a gravel bike.